|

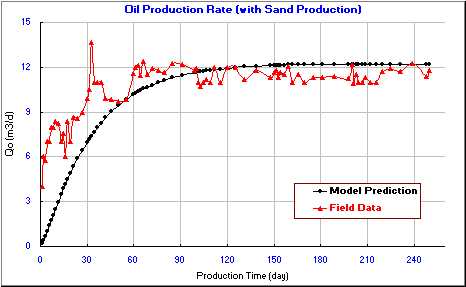

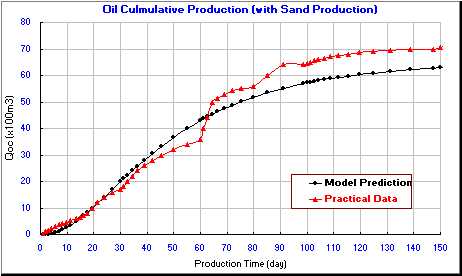

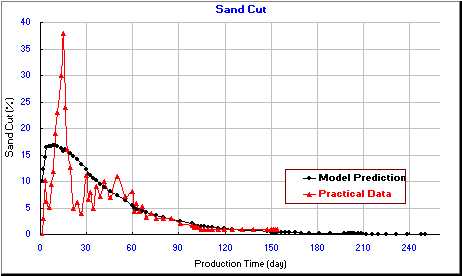

Field Example 1 : Enhanced production by allowing a certain amount sand production: We helped CNPC to design their sand producing well in oversea field. Screen was implemented inside casing for sand control. A production rate of 41 m^3/day in average was obtained. Based on our COMPUTING s, a 5-8 times production increase can be obtained if we allow a certain amount sand can be produced, yet such a sand production will stop after a certain period of time. Re-completion gave CNPC more than 150 m^3/day for all four trial wells, major surface construction and pipeline design were implemented afterward. Such a sand rate COMPUTING proves to be vital for a company to forecast their productivity and related engineering design such as production and surface transportation. Not only they received local government approval for the project, but they expect a much higher production and profit. The theoretical background and some discussions can be found in JPT and SPE Formation Evaluation 2002 by Wang and Chen. Field Example 2: Predicting onset of sand production: extensive onset sand prediction services provided to Elf Aquetaine, CNOOC, UNOCAL, PETROCHINA, etc. . Case #1 : Elf Aquetaine The onset of sand production for deviated gas well was the major concern. In their field, more than 70% wells were facing this issue if these wells are producing sand, as at least $150,000.00 USD would be required in each of these wells if sand control is required. Our studies confirmed that perforating with a certain angle against the in-situ stresses can reduce sanding risk. Case #2 : CNOOC In their off-shore reservoir, 33 wells were in production and 3 of the wells were already producing sand which were forced to be closed. Using the data from the 3 sand producing wells, we successfully predicted the other 30 wells. Among these 30 wells, only 2 wells which were predicted to produce sand at a later stage of production produced sand at the very beginning of the production, all other 27 wells did not produce sand within the predicting range. Case #3 : UNOCAL A large oil reserve was planned to be developed in the next two years. Our AGENTS wanted to evaluate the realistic productivity as these formations contain multiple pay zones and some of them are poorly consolidated. Foot-by-foot examination and prediction indicated that the weak formation is located in a certain depth, a isolation for this zone during production is necessary in order not to produce sand yet maintain a high production. UNOCAL adjusted their production and surface operational plan according to our critical production rate prediction. Field Example 3: Sand prediction for well completion screening for horizontal well Two cases are presented here one for Petrochina on shore and one for CNPC oversea project. Petrochina owns a high-rate oil reservoir which has been in a high-rate production. Since 2004, a production declining plan was forced in as sand wuold have been produced if a certain drawdown was exceeded. Gravel packing was proposed in some of the wells, a minimum production reduction of 25% were forecasted based on SAND_PRO. A 200 meter long horizontal well was recommended by PGI, and a similar production level was maintained afterward, yet no sand was produced. The CNPC oversea project was similar to the Petrochina case, except CNPC’s reservoir is much more thin. There are two pay zones in this region, however the deeper pay zone which has less productivity was selected for production as this higher productivity formation were facing more sand production. Sand control was proved to be more costly with less production, a horizontal well was also recommend based on SAND_PRO COMPUTING s, which led to a sand-free producing horizontal well. Field Example 4: Producing Oil with Massive Sand Production This is a typical Northwestern Alberta case, where our focus is to manage the sand rate for oil enhancement. Both an erosion model and wormhole models were used for this field case, cumulative sand production and the enhanced productivity were matched with the field history. Several SPE papers on these field studies and discussions can be found in PGI’s website. Field Example 5: Tectonic stress and Fracture In the carbonate stone of the Ordovician formation in Tahe oil field,well performance after Acid-fracturing are poor and need improvement.The stress change around fault affects the suitability of the fracturing design.In this case ,sample wells data and geology structure information are colected and analized , then multiple regression and finite element method are used to simulate the stress distribution and alternation near fault . these special stress state provide accurate basic information for fractuirng design. furthermore ,the effect on HF iniationation and propagation of fault ,natural fratures and the altered stress are studied .these will be great means of reservoir stimulation and production . Field Example 6: Fracture geometry and Plastic deformation This is a typical case in shale gas fracturing in Fuling and pengshui shales gas zone ,where the hydraulic fracture are diffcult to open and proppants cannot be putinto them . this project focus on the effects of shale elastic and plastic deformation on fracture initiation and geometry. With finite element method, model for fracture initiation and geometry are developed .The stress alteration and plastic deformation area are modeled and evaluated. fracture initiation pressure and geometry are calculated with stress shadow and plastic deformation in consideration. Furthermore , multi layers were modeled and fracture width in different layers are calculated. All these study and modeling will provide reference for optimal hydraulic fractuing design in shale gas . Field Example 7: Declining production of fractured carbonate Conventionally, after long time production and reservoir pressur declining,redcing the bottomhole pressure is an effective method to improve or maintain the oil rate . however ,Once the stress-permeability sensitivity is an typical feature in the formation , especially in naturally fractured reservoir ,such as the carbonate stone of the Ordovician formation in Tahe oil field, Decreasing bottomhole pressure may cause completely reverse consequence. Because in formation with stress-permeability sensitivity, Decreasing bottomhole pressure usually result in increasing of effect stress , which cause decreasing of permeability .then production performance will decline .in this case model for production predition was developed.base on the permeability-stress sensitivity experiment, a model of permeability-stress sensitivity and the permeability index was developed with regression . with the production predition model and permeability-stress sensitivity index, we analyze the effect of permeability-stress sensitivity index on production.Furthermore ,optimal bottomhole pressure schedule was caulted by several cases modeling with the production predition model and permeability-stress sensitivity index .in otherwise ,optimal water injection shcedule can be also realised with this model ,then the permeability in formation will be improvied ,as well as the water injection volume and the reservoir pressur .in the end ,the production performance will be improvied .

|